and Detail Drawings

Wales

England

- Offices

- Shops / Commercial

- Industrial Buildings

- Storage / Assembly Buildings

- Other Non-Residential

Building Regulations Specifications - Examples

Here are some examples of our Building Regulations Specifications.

Note: each of these notes is incomplete. Please register here to use our full Building Regulations Specs.

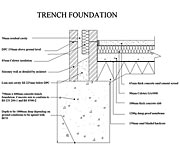

Strip Foundation

Provide 225mm x 600mm concrete foundation, concrete mix to conform to BS EN 206:2013 and BS 8500-2.

All foundations to be a minimum of 1000mm below ground level, exact depth to be agreed on site with Building Control Officer to suit site conditions.

All constructed in accordance with 2010 Building Regulations A1/2 and BS 8004:2015 Code of Practice for Foundations.

Ensure foundations are constructed below invert level of any adjacent drains.

Base of foundations supporting internal walls to be.....register here for our full specifications and web apps.

Add To Basket

Includes DXF,

DWG & JPG

Solid Ground Floor (Insulation Over Slab)

To meet min U value required of 0.18 W/m²K

P/A ratio 0.5

Solid ground floor to consist of 150mm consolidated well-rammed hardcore, blinded with 50mm sand blinding. Provide 100mm ST2 or Gen2 ground bearing slab concrete mix to conform to BS 8500-2 over a 1200 gauge polythene DPM. DPM to be lapped in with DPC in walls. Floor to be insulated over slab and DPM with min 90mm thick Celotex GA4000 insulation.

25mm insulation to continue around floor perimeters to avoid thermal bridging. A VCL should be laid over the insulation boards and turned up 100mm at room perimeters behind the skirting, all joints to be .....register here for our full specifications and web apps.

Timber Suspended Floor

Ground preparation - Remove top soil and vegetation, apply total weed killer and 150mm min thick sand blinded hardcore, then either – (i) Provide concrete ground cover of at least 100mm thick or (ii) Prepare the ground to an even surface and lay a ground cover of concrete at least 50mm thick, on a damp-proof membrane of at least 1200 gauge polyethylene, laid on a bed of fine sand blinding. Floor construction - min 20mm tongue and groove softwood boards or moisture resistant particle/chipboard grade type C4 to BS EN 312:2010 as required. Lay with staggered joints on 47mm x 100mm C24 grade soft wood joists at maximum 400mm centres max span 2.10m. Joists to be supported off proprietary galvanized joist hangers built into new masonry walls or fixed to treated timber wall plates resin bolted to walls at 600mm centres. If required, floor joists also to be To meet min U value required of 0.18 W/m²K

gk not more than 0.5

Ground preparation -Remove top soil and vegetation, apply total weed killer and 150mm min thick sand blinded hardcore, then either –

(i) Provide concrete ground cover of at least 100mm thick or

(ii) Prepare the ground to an even surface and lay a ground cover of concrete at least 50mm thick, on a damp-proof membrane of at least 1200 gauge polyethylene, laid on a bed of fine blinding material.

Floor construction - min 20mm tongue and groove softwood boards or moisture resistant particle/chipboard grade type C4 to BS EN 312:2010 as required.

Lay with staggered joints on 47mm x 145mm C24 grade soft wood joists at maximum 400mm centres, max span 3.21m. Joists to be supported off proprietary galvanized joist hangers built into new masonry walls or fixed to treated timber wall plates resin bolted to walls at 600mm centres. If required, floor joists also to be .....register here for our full specifications and web apps.

Block and Beam Floor

To meet min U value required of 0.18 W/m²K

Remove top soil and vegetation and apply weed killer – provide 50mm concrete ground cover if required by BCO.

The underside of beams to be not less than 150mm above the top of the ground. PCC beams to be supplied and fixed to beam manufacturer's plan, layout and details (details and calculations to be sent to Building Control for approval before works commence). Beam to have a minimum bearing of 100mm onto DPC and load bearing walls.

Provide concrete blocks to BS EN 772-2, wet and grout all joints with 1:4 cement/sand mix. Provide double beams below non-load bearing partitions.

Lay 1200g DPM/radon barrier over beam and block floor, with 300mm laps double welted and taped at joints and service entry points using radon gas proof tape.

Lay floor insulation over DPM, 90mm Celotex GA4000 applied as a rigid material. 25mm insulation to continue around floor perimeters to avoid thermal bridging.

Lay 500g separating layer over insulation and provide 75mm sand/cement screed over and prepare for.....register here for our full specifications and web apps.

Solid External Wall

To achieve min U-value 0.18 W/m²K

Construct solid wall at least 215mm thick constructed using concrete blocks.

Rake out joints in the wall to a depth of at least 10mm and apply two coats of render at least 20mm thick with a scraped or textured finish.

The rendering mix to comply to BS EN 13914-1 with waterproof additive. Insulate wall on the inside using 100mm Celotex GA4000 insulation. Finish with 12.5mm plasterboard over vcl and 3mm skim coat of.....register here for our full specifications and web apps.

Cavity Wall (Full Fill)

To achieve minimum U Value of 0.18 W/m²K

20mm two coat sand/cement render to comply to BS EN 13914-1 with waterproof additive on 100mm lightweight block, 0.15 W/m²K, e.g. Celcon solar, Toplite Standard.

Fully fill the cavity with 150mm Dritherm 32 cavity insulation as manufacturer's spec.

Inner leaf to be.....register here for our full specifications and web apps.

This is just a Small Sample from our Drawing Library.

Timber Frame Wall

To achieve minimum U Value of 0.18 W/m²K

Outer skin to be 102mm suitable facing brick with 50mm vented and drained cavity provided between the stud and brick cladding.

Inner stud to have breathable membrane (a vapour resistance of not more than 0.6 MNs/g) fixed to 12mm thick W.B.P external quality plywood sheathing (or other approved).

Ply fixed to treated timber frame studs constructed using 150mm x 50mm treated timbers with head and sole plates and vertical studs (with noggins) at 400mm ctrs, or to s/engineer's details and calculations.

Insulation to be 70mm Kingspan Kooltherm between studs with .....register here for our full specifications and web apps.

Solid Brick Wall, External Insulation

To achieve minimum U Value of 0.18 W/m²K

Mechanically fix 100mm Kingspan Kooltherm K5 external wall board to 215mm solid brick wall built using 1:1:6 cement mortar.

Insulation boards to be fixed using thermally broken proprietary telescopic tube fasteners at max 1m centres driven into pre-drilled holes, ensure a minimum of 5 fixings per insulation board.

Apply 20mm of suitable reinforced render with waterproof additive with a scraped or textured finish. Render to be applied directly to the insulation incorporating eml or glass fibre mesh.

Movement joints to.....register here for our full specifications and web apps.

Ventilated Flat Roof

To achieve U value of 0.15 W/m²K

Flat roof to be single ply membrane roofing with aa fire rating as specialist specification, with a current BBA or WIMLAS Certificate on 22mm exterior grade plywood, laid on firrings to give a 1:40 fall on 47 x 150mm grade C24 timber joists at 400 ctrs, max span 3.22m (see Engineer's details for sizes).

Cross-ventilation to be provided on opposing sides by a proprietary eaves ventilation strip to give 25mm continuous ventilation, with fly proof screen.

Flat roof insulation is to be continuous with the wall insulation but stopped back to allow a continuous 50mm air gap above the insulation for ventilation.

Insulation to be .....register here for our full specifications and web apps.

Warm Flat Roof

To achieve U value 0.15 W/m²K

12.5mm spa solar reflective chippings to achieve aa designated fire rating for surface spread of flame bedded in bitumen on three layer felt to BS 6229 laid on 18mm external quality ply (ply optional, see manufacturer's details) over 150mm Celotex XR4000 insulation.

Insulation bonded to VCL fixed to 18mm exterior grade plywood on firrings to give 1:40 fall on 47 x 145mm C24 timber joists at 400 ctrs to give a max span of 3.22m (see Engineer's details for sizes).

Ceiling construction to be 12.5mm plasterboard over vapour barrier with skim plaster finish.

Provide restraint to .....register here for our full specifications and web apps.

Pitched Roof (Ceiling Level Insulation)

To achieve U value of 0.15 W/m²K

Timber roof structures to be designed by an Engineer in accordance with NHBC Technical Requirement R5 Structural Design. Calculations to be based on BS EN 1995-1-1:2004 Eurocode 5: Design of timber structures. Roofing tiles to match existing on 25 x 38mm tanalised sw treated battens on breathable felt supported on 47 x 100mm grade C24 rafters at max 400mm centres, max span 2.12m. Rafters supported on 100 x 50mm sw wall plates.

Insulation at ceiling level to be 150mm XR4000 Celotex between ceiling joists with a further 40mm TB4000 over joists. 18mm chipboard to be provided over insulation.

Construct ceiling using sw joists at 400mm centres, finished internally with 12.5mm plasterboard and min 3mm thistle multi-finish plaster. Provide polythene vapour barrier between insulation and plasterboard.

Where required provide opening at eaves level at least equal to continuous strip 25mm wide on two opposite sides to promote cross-ventilation and provide mono pitched roofs with ridge/high level ventilation equivalent to a 5mm gap via proprietary tile vents spaced in accordance with manufacturer’s details.

Restraint strapping - 100mm x 50mm wall plate strapped down to walls. Ceiling joists and .....register here for our full specifications and web apps.

Pitched Roof (Unvented)

To achieve min U-value required of 0.15 W/m²K

Timber roof structures to be designed by an Engineer in accordance with NHBC Technical Requirement R5 Structural Design.

Calculations to be based on BS EN 1995-1-1:2004 Eurocode 5: Design of timber structures.

Roofing tiles to match existing fixed to tile battens secured over breathable felt to relevant BBA Certificate allowing the breather felt to sag at least 10mm over preservative-treated counter battens (min 38mm x 50mm).

Provide 100mm Celotex GA4000 insulation boards under the counter battens and 40mm Celotex TB4000 between 47 x 100mm timber rafters strength class C24 at 400 c/c – to give a max 2.12m span.

A vapour control layer should be provided to the underside of the rafters. Finish with 12.5mm plasterboard and skim.....register here for our full specifications and web apps.

Stairs

Dimensions to be checked and measured on site prior to fabrication of stairs. Timber stairs to comply with BS585 and with Part K of the Building Regulations. Max rise 220mm, min going 220mm. Two risers plus one going should be between 550 and 700mm.

Tapered treads to have going in centre of tread at least the same as the going on the straight. Min 50mm going of tapered treads measured at narrow end.

Pitch not to exceed 42 degrees. The width and length of every landing should be at least as great as the smallest width of the flight.

Doors which swing across a landing at the bottom of a flight should leave a clear space of at least 400mm across the full width of the flight. Min 2.0m headroom measured vertically above pitch line of stairs and landings.....register here for our full specifications and web apps.

Extract Ventilation, Utility Room

To utility room provide mechanical ventilation ducted to external air capable of extracting at a rate of 30 l/s.

Internal doors should be provided with a 10mm gap below the door to aid air circulation.

Ventilation provision in accordance with the Domestic Ventilation Compliance Guide.

Intermittent extract fans to.....register here for our full specifications and web apps.

Drainage (Above Ground)

All new above ground drainage and plumbing to comply with BS EN 12056-2 for sanitary pipework.

All drainage to be in accordance with Part H of the Building Regulations. Wastes to have 75mm deep anti-vac bottle traps and rodding eyes to be provided at changes of direction.

Size of wastes pipes and max length of branch connections (if max length is exceeded then anti-vac traps to be used)

Wash basin - 1.7m for 32mm pipe 3m for 40mm pipe

Bath/shower - 3m for 40mm pipe 4m for 50mm pipe

W/c - 6m for 100mm pipe for single WC

All branch pipes to connect to 110mm soil and vent pipe terminating min 900mm above any openings.....register here for our full specifications and web apps.

Tanking

Sika® Damp-proofing Slurry polymer - cement based waterproofing system. Manfacturer's details must be followed.

Type A waterproofing in accordance with BS 8102: 1990 to give a protection level of grade 3 (suitable for concrete, renders, brickwork and blockwork structures as detailed in BBA certificate).

Ensure that all materials and products are compatible. Assess structure for suitability of tanking system and ensure substructure is free draining.

The concrete surface must be examined for defects and repaired in accordance with manufacturer's details if required.

All retaining elements are to be detailed by a Structural Engineer.

All materials and products should be installed by a competent contractor strictly in accordance with the manufacturer’s recommendations, BS 8102 and BBA certificate.

All surfaces must be clean, sound and free from surface water.

Surfaces to be prepared for waterproofing system by being bush hammered, scabbled or sandblasted and then wetted down. All defective mortar joints raked out, squarely 10mm to 12mm deep and the surface washed thoroughly. Wall treatment Apply a minimum of two coats to give a total thickness of between.....register here for our full specifications and web apps.

Pitched Roof (Vented)

To achieve min U-value required of 0.15 W/m²K

Timber roof structures to be designed by an Engineer in accordance with NHBC Technical Requirement R5 Structural Design.

Calculations to be based on BS EN 1995-1-1:2004 Eurocode 5: Design of timber structures.

Roofing tiles to match existing fixed to tile battens secured over breathable felt to relevant BBA Certificate allowing the breather felt to sag at least 10mm over preservative-treated counter battens (min 38mm x 50mm).

Provide 75mm Kingspan Thermapitch TP10 insulation boards under the counter battens and 75mm Kingspan Thermapitch TP10 between 47 x 195mm timber rafters strength class C24 at 600 c/c – span to Engineer's details.

A vapour control layer should be provided to the underside of the rafters. Finish with 12.5mm plasterboard and skim.

Restraint strapping - Ceiling joists tied to rafters.....register here for our full specifications and web apps.

Cavity Wall (Partial Fill)

To achieve minimum U Value of 0.18 W/m²K

Provide 103mm suitable facing brick. Ensure a 50mm clear residual cavity and provide 85mm Celotex CW4000 insulation fixed to internal leaf constructed of 100mm, 0.15 W/m²K lightweight block.....register here for our full specifications and web apps.

Solid Ground Floor (Insulation Under Slab)

To meet min U value required of 0.18 W/m²K

P/A ratio 0.5

Solid ground floor to consist of 150mm consolidated well-rammed hardcore, blinded with 50mm sand blinding.

Provide a 1200 gauge polythene DPM, DPM to be lapped in with DPC in walls.

Floor to be insulated over DPM with 90mm thick Celotex GA4000 insulation.

25mm insulation to continue around floor perimeters to avoid thermal bridging. A VCL should be laid over the insulation boards and turned up 100mm at room perimeters behind the skirting, all joints to be lapped by 150mm and sealed.

Provide 100mm ST2 or Gen2 ground bearing slab concrete mix to conform to BS 8500-2 over VCL.

Finish over the slab with a floating layer of min 20mm tongue and groove softwood boards or moisture resistant particle/chipboard grade type C4 to BS EN 312:2010 as required.

Lay with staggered joints.

Where drain runs pass.....register here for our full specifications and web apps.

To begin compiling your Building Regulations Specification with our App, choose either House Extension, New Build, Flat Conversion, Loft Conversion or Garage Conversion.

Building Regulations Specifications - Examples

Here are some examples of our Building Regulations Specifications.

Note: each of these notes is incomplete. Please register here to use our full Building Regulations Specs.

Strip Foundation

Provide 225mm x 600mm concrete foundation, concrete mix to conform to BS EN 206:2013 and BS 8500-2.

All foundations to be a minimum of 1000mm below ground level, exact depth to be agreed on site with Building Control Officer to suit site conditions.

All constructed in accordance with 2010 Building Regulations A1/2 and BS 8004:2015 Code of Practice for Foundations.

Ensure foundations are constructed below invert level of any adjacent drains.

Base of foundations supporting internal walls to be.....register here for our full specifications and web apps.

Add To Basket

Includes

DWG and Jpeg

Add To Basket

Includes

DWG and Jpeg

Solid Ground Floor (Insulation Over Slab)

To meet min U value required of 0.18 W/m²K

P/A ratio 0.5

Solid ground floor to consist of 150mm consolidated well-rammed hardcore, blinded with 50mm sand blinding. Provide 100mm ST2 or Gen2 ground bearing slab concrete mix to conform to BS 8500-2 over a 1200 gauge polythene DPM. DPM to be lapped in with DPC in walls. Floor to be insulated over slab and DPM with min 90mm thick Celotex GA4000 insulation.

25mm insulation to continue around floor perimeters to avoid thermal bridging. A VCL should be laid over the insulation boards and turned up 100mm at room perimeters behind the skirting, all joints to be .....register here for our full specifications and web apps.

Timber Suspended Floor

To meet min U value required of 0.18 W/m²K

gk not more than 0.5

Ground preparation -Remove top soil and vegetation, apply total weed killer and 150mm min thick sand blinded hardcore, then either –

(i) Provide concrete ground cover of at least 100mm thick or

(ii) Prepare the ground to an even surface and lay a ground cover of concrete at least 50mm thick, on a damp-proof membrane of at least 1200 gauge polyethylene, laid on a bed of fine blinding material.

Floor construction - min 20mm tongue and groove softwood boards or moisture resistant particle/chipboard grade type C4 to BS EN 312:2010 as required.

Lay with staggered joints on 47mm x 145mm C24 grade soft wood joists at maximum 400mm centres, max span 3.21m. Joists to be supported off proprietary galvanized joist hangers built into new masonry walls or fixed to treated timber wall plates resin bolted to walls at 600mm centres. If required, floor joists also to be .....register here for our full specifications and web apps.

Block and Beam Floor

To meet min U value required of 0.18 W/m²K

Remove top soil and vegetation and apply weed killer – provide 50mm concrete ground cover if required by BCO.

The underside of beams to be not less than 150mm above the top of the ground. PCC beams to be supplied and fixed to beam manufacturer's plan, layout and details (details and calculations to be sent to Building Control for approval before works commence). Beam to have a minimum bearing of 100mm onto DPC and load bearing walls.

Provide concrete blocks to BS EN 772-2, wet and grout all joints with 1:4 cement/sand mix. Provide double beams below non-load bearing partitions.

Lay 1200g DPM/radon barrier over beam and block floor, with 300mm laps double welted and taped at joints and service entry points using radon gas proof tape.

Lay floor insulation over DPM, 90mm Celotex GA4000 applied as a rigid material. 25mm insulation to continue around floor perimeters to avoid thermal bridging.

Lay 500g separating layer over insulation and provide 75mm sand/cement screed over and prepare for .....register here for our full specifications and web apps.

Solid External Wall

To achieve min U-value 0.18 W/m²K

Construct solid wall at least 215mm thick constructed using concrete blocks.

Rake out joints in the wall to a depth of at least 10mm and apply two coats of render at least 20mm thick with a scraped or textured finish.

The rendering mix to comply to BS EN 13914-1 with waterproof additive. Insulate wall on the inside using 100mm Celotex GA4000 insulation. Finish with 12.5mm plasterboard over vcl and 3mm skim coat of.....register here for our full specifications and web apps.

Cavity Wall (Full Fill)

To achieve minimum U Value of 0.18 W/m²K

20mm two coat sand/cement render to comply to BS EN 13914-1 with waterproof additive on 100mm lightweight block, 0.15 W/m²K, e.g. Celcon solar, Toplite Standard.

Fully fill the cavity with 150mm Dritherm 32 cavity insulation as manufacturer's spec.

Inner leaf to be.....register here for our full specifications and web apps.

Timber Frame Wall

To achieve minimum U Value of 0.18 W/m²K

Outer skin to be 102mm suitable facing brick with 50mm vented and drained cavity provided between the stud and brick cladding.

Inner stud to have breathable membrane (a vapour resistance of not more than 0.6 MNs/g) fixed to 12mm thick W.B.P external quality plywood sheathing (or other approved).

Ply fixed to treated timber frame studs constructed using 150mm x 50mm treated timbers with head and sole plates and vertical studs (with noggins) at 400mm ctrs, or to s/engineer's details and calculations.

Insulation to be 70mm Kingspan Kooltherm between studs with .....register here for our full specifications and web apps.

Solid Brick Wall, External Insulation

To achieve minimum U Value of 0.18 W/m²K

Mechanically fix 100mm Kingspan Kooltherm K5 external wall board to 215mm solid brick wall built using 1:1:6 cement mortar.

Insulation boards to be fixed using thermally broken proprietary telescopic tube fasteners at max 1m centres driven into pre-drilled holes, ensure a minimum of 5 fixings per insulation board.

Apply 20mm of suitable reinforced render with waterproof additive with a scraped or textured finish. Render to be applied directly to the insulation incorporating eml or glass fibre mesh.

Movement joints to.....register here for our full specifications and web apps.

Ventilated Flat Roof

To achieve U value of 0.15 W/m²K

Flat roof to be single ply membrane roofing with aa fire rating as specialist specification, with a current BBA or WIMLAS Certificate on 22mm exterior grade plywood, laid on firrings to give a 1:40 fall on 47 x 150mm grade C24 timber joists at 400 ctrs, max span 3.22m (see Engineer's details for sizes).

Cross-ventilation to be provided on opposing sides by a proprietary eaves ventilation strip to give 25mm continuous ventilation, with fly proof screen.

Flat roof insulation is to be continuous with the wall insulation but stopped back to allow a continuous 50mm air gap above the insulation for ventilation.

Insulation to be .....register here for our full specifications and web apps.

Warm Flat Roof

To achieve U value 0.15 W/m²K

12.5mm spa solar reflective chippings to achieve aa designated fire rating for surface spread of flame bedded in bitumen on three layer felt to BS 6229 laid on 18mm external quality ply (ply optional, see manufacturer's details) over 150mm Celotex XR4000 insulation.

Insulation bonded to VCL fixed to 18mm exterior grade plywood on firrings to give 1:40 fall on 47 x 145mm C24 timber joists at 400 ctrs to give a max span of 3.22m (see Engineer's details for sizes).

Ceiling construction to be 12.5mm plasterboard over vapour barrier with skim plaster finish.

Provide restraint to .....register here for our full specifications and web apps.

Pitched Roof (Ceiling Level Insulation)

To achieve U value of 0.15 W/m²K

Timber roof structures to be designed by an Engineer in accordance with NHBC Technical Requirement R5 Structural Design. Calculations to be based on BS EN 1995-1-1:2004 Eurocode 5: Design of timber structures. Roofing tiles to match existing on 25 x 38mm tanalised sw treated battens on breathable felt supported on 47 x 100mm grade C24 rafters at max 400mm centres, max span 2.12m. Rafters supported on 100 x 50mm sw wall plates.

Insulation at ceiling level to be 150mm XR4000 Celotex between ceiling joists with a further 40mm TB4000 over joists. 18mm chipboard to be provided over insulation.

Construct ceiling using sw joists at 400mm centres, finished internally with 12.5mm plasterboard and min 3mm thistle multi-finish plaster. Provide polythene vapour barrier between insulation and plasterboard.

Where required provide opening at eaves level at least equal to continuous strip 25mm wide on two opposite sides to promote cross-ventilation and provide mono pitched roofs with ridge/high level ventilation equivalent to a 5mm gap via proprietary tile vents spaced in accordance with manufacturer’s details.

Restraint strapping - 100mm x 50mm wall plate strapped down to walls. Ceiling joists and .....register here for our full specifications and web apps.

Pitched Roof (Unvented)

To achieve min U-value required of 0.15 W/m²K

Timber roof structures to be designed by an Engineer in accordance with NHBC Technical Requirement R5 Structural Design.

Calculations to be based on BS EN 1995-1-1:2004 Eurocode 5: Design of timber structures.

Roofing tiles to match existing fixed to tile battens secured over breathable felt to relevant BBA Certificate allowing the breather felt to sag at least 10mm over preservative-treated counter battens (min 38mm x 50mm).

Provide 100mm Celotex GA4000 insulation boards under the counter battens and 40mm Celotex TB4000 between 47 x 100mm timber rafters strength class C24 at 400 c/c – to give a max 2.12m span.

A vapour control layer should be provided to the underside of the rafters. Finish with 12.5mm plasterboard and skim.....register here for our full specifications and web apps.

Stairs

Dimensions to be checked and measured on site prior to fabrication of stairs. Timber stairs to comply with BS585 and with Part K of the Building Regulations. Max rise 220mm, min going 220mm. Two risers plus one going should be between 550 and 700mm.

Tapered treads to have going in centre of tread at least the same as the going on the straight. Min 50mm going of tapered treads measured at narrow end.

Pitch not to exceed 42 degrees. The width and length of every landing should be at least as great as the smallest width of the flight.

Doors which swing across a landing at the bottom of a flight should leave a clear space of at least 400mm across the full width of the flight. Min 2.0m headroom measured vertically above pitch line of stairs and landings.....register here for our full specifications and web apps.

Extract Ventilation, Utility Room

To utility room provide mechanical ventilation ducted to external air capable of extracting at a rate of 30 l/s.

Internal doors should be provided with a 10mm gap below the door to aid air circulation.

Ventilation provision in accordance with the Domestic Ventilation Compliance Guide.

Intermittent extract fans to.....register here for our full specifications and web apps.

Drainage (Above Ground)

All new above ground drainage and plumbing to comply with BS EN 12056-2 for sanitary pipework.

All drainage to be in accordance with Part H of the Building Regulations. Wastes to have 75mm deep anti-vac bottle traps and rodding eyes to be provided at changes of direction.

Size of wastes pipes and max length of branch connections (if max length is exceeded then anti-vac traps to be used)

Wash basin - 1.7m for 32mm pipe 3m for 40mm pipe

Bath/shower - 3m for 40mm pipe 4m for 50mm pipe

W/c - 6m for 100mm pipe for single WC

All branch pipes to connect to 110mm soil and vent pipe terminating min 900mm above any openings.....register here for our full specifications and web apps.

Tanking

Sika® Damp-proofing Slurry polymer - cement based waterproofing system. Manfacturer's details must be followed.

Type A waterproofing in accordance with BS 8102: 1990 to give a protection level of grade 3 (suitable for concrete, renders, brickwork and blockwork structures as detailed in BBA certificate).

Ensure that all materials and products are compatible. Assess structure for suitability of tanking system and ensure substructure is free draining.

The concrete surface must be examined for defects and repaired in accordance with manufacturer's details if required.

All retaining elements are to be detailed by a Structural Engineer.

All materials and products should be installed by a competent contractor strictly in accordance with the manufacturer’s recommendations, BS 8102 and BBA certificate.

All surfaces must be clean, sound and free from surface water.

Surfaces to be prepared for waterproofing system by being bush hammered, scabbled or sandblasted and then wetted down. All defective mortar joints raked out, squarely 10mm to 12mm deep and the surface washed thoroughly. Wall treatment Apply a minimum of two coats to give a total thickness of between.....register here for our full specifications and web apps.

Pitched Roof (Vented)

Timber roof structures to be designed by an Engineer in accordance with NHBC Technical Requirement R5 Structural Design.

Calculations to be based on BS EN 1995-1-1:2004 Eurocode 5: Design of timber structures.

Roofing tiles to match existing fixed to tile battens secured over breathable felt to relevant BBA Certificate allowing the breather felt to sag at least 10mm over preservative-treated counter battens (min 38mm x 50mm).

Provide 75mm Kingspan Thermapitch TP10 insulation boards under the counter battens and 75mm Kingspan Thermapitch TP10 between 47 x 195mm timber rafters strength class C24 at 600 c/c – span to Engineer's details.

A vapour control layer should be provided to the underside of the rafters. Finish with 12.5mm plasterboard and skim.

Restraint strapping - Ceiling joists tied to rafters.....register here for our full specifications and web apps.

Cavity Wall (Partial Fill)

To achieve minimum U Value of 0.18 W/m²K

Provide 103mm suitable facing brick. Ensure a 50mm clear residual cavity and provide 85mm Celotex CW4000 insulation fixed to internal leaf constructed of 100mm, 0.15 W/m²K lightweight block.....register here for our full specifications and web apps.

Solid Ground Floor (Insulation Under Slab)

To meet min U value required of 0.18 W/m²K

P/A ratio 0.5

Solid ground floor to consist of 150mm consolidated well-rammed hardcore, blinded with 50mm sand blinding.

Provide a 1200 gauge polythene DPM, DPM to be lapped in with DPC in walls.

Floor to be insulated over DPM with 90mm thick Celotex GA4000 insulation.

25mm insulation to continue around floor perimeters to avoid thermal bridging. A VCL should be laid over the insulation boards and turned up 100mm at room perimeters behind the skirting, all joints to be lapped by 150mm and sealed.

Provide 100mm ST2 or Gen2 ground bearing slab concrete mix to conform to BS 8500-2 over VCL.

Finish over the slab with a floating layer of min 20mm tongue and groove softwood boards or moisture resistant particle/chipboard grade type C4 to BS EN 312:2010 as required.

Lay with staggered joints.

Where drain runs pass.....register here for our full specifications and web apps.

To begin compiling your Building Regulations Specification for submission to Building Control or your Approved Inspector with our Web Apps, choose either:

House Extension, New Build, Flat Conversion, Loft Conversion, Garage Conversion, New Build Flats, Basement Conversion or Garage Build.